Value Delivered

ECM helped upgrade airflow technology at 98 research laboratories on the Georgia Tech campus. Alongside our ESCO client ABM, we won the right to serve as the design-build contractor after completing a three-lab competitive pilot that demonstrated impressive safety improvements and cost savings.

The completed project helped reduce energy use by 73.7-percent, and actual year one energy savings were $192,984. The project also received $75,000 in Georgia Power rebates and expects another $139,554 in future rebates.

Client Objectives

The client wanted to improve safety, functionality, and energy efficiency to save on utility costs and reduce their carbon footprint.

Solutions

We provided consulting services, materials, design assistance, project management, and building management systems integration for the project. Our team also trained ABM personnel to install, commission, and support advanced laboratory technology.

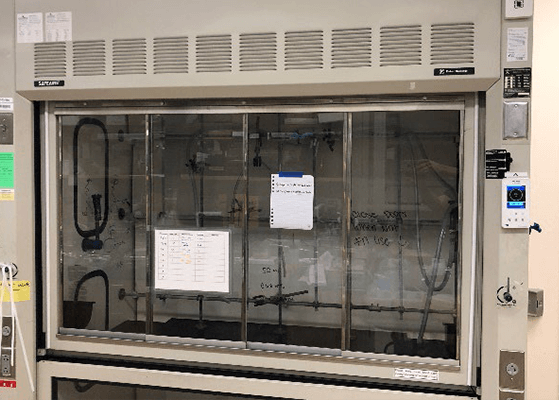

The core of the project was a variable air volume (VAV) retrofit that included the installation of the following cutting-edge TEL equipment:

- 139 VAV fume hood controllers (TEL’s AFA4000)

- 160 auto sash closers

- 150 snorkel exhaust control systems

- 96 lab space controllers (TEL’s AFA5000)

Additionally, the project required the re-coding of core software parameters to help achieve the most remote controllability possible. Our team developed software that provide real-time, air-change-per-hour reporting on the screen of TEL’s AFA 5000 controllers. This allows University staff to precisely match system metrics with their operational goals.

Client Background

Established in 1885, the Georgia Institute of Technology is a public research university located in Atlanta, GA, serving nearly 50,000 students.