Higher Education

ATLANTA, GA

Georgia Tech University

ECM won this design-build laboratory airflow project after a competitive pilot program demonstrated impressive safety improvements and cost savings.

Adams State University

ECM identified and completed weatherization improvements at sixteen campus buildings, helping increase efficiency and save energy.

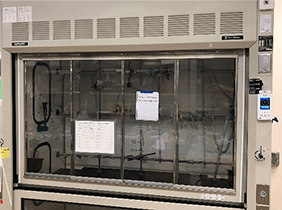

Colorado State University Pueblo

Our team retrofitted 39 chemical fume hoods from CAV to VAV controls, addressing inefficiency and safety concerns.

East Central University

We replaced thirteen fume hoods and added exhaust redundancy at this campus, generating significant cost savings without increasing the client’s capital budget.

Edgewood College

We provided TEL airflow controls that helped kitchens at this college save energy, reduce noise levels, decrease grease entrapment, and reduce HVAC wear.

Kansas State University Vet Med Center

And end-to-end cooling tower rehab will help restore the structural integrity of the system and prevent the growth of potentially harmful micro-organisms and bacteria.

Ripon College

We installed new, cutting-edge TEL controls for a dozen chemical fume hoods and three kitchen hoods at this liberal arts college.

University of Texas at Austin

Annual energy savings from this lighting retrofit are 28.5 million kWh.