Value Delivered

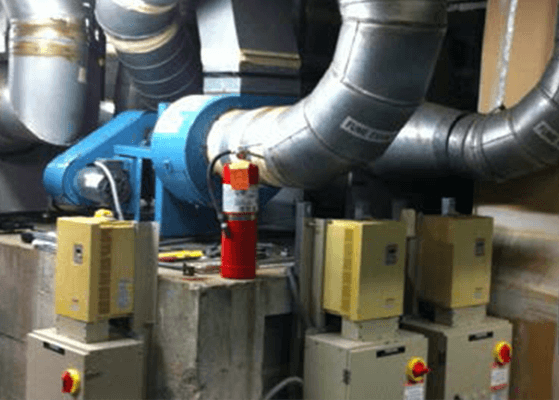

US Pharmacopeia (USP) had constant air volume (CAV) fume hoods and snorkel exhausts in 19 laboratories scattered over two buildings. ECM served as the design-build contractor that converted all of these lab airflow systems from CAV to variable air volume (VAV) utilizing cutting-edge TEL equipment.

This retrofit won a highly competitive energy efficiency grant from the Maryland Energy Administration, providing $522,015 in incentives. Annual energy savings are projected at over 1 million kilowatt hours and over 60,000 therms, for a total of $187,542. Simple payback for the project is less than two years.

Client Objectives

USP wanted to upgrade their laboratory facilities in order to improve airflow management and reduce operating costs.

Solutions

Our team provided the following design-build services:

- Upgraded 32 fume hood system with TEL AFA 1000/E VAV controllers

- Fume hoods are equipped with audio and visual alarms directing users to close combination sashes left open for more than five minutes

- Each controller modulates a fast-acting actuator that is retrofit to an existing valve or new mono-blade damper to contain and control face velocity

- Installed TEL room pressure controllers that modulate supply air to maintain negative air pressure

Additionally, we also worked with Siemens to integrate the TEL controls into the existing building management system through a BACnet interface. This provides data point visibility through Siemens’ front end. The system includes a night setback protocol to help reduce air change rates when the labs are unoccupied.

Client Background

USP is an independent, nonprofit organization that is dedicated to setting scientific standards in compounding, biologics, pharmaceutical manufacturing, and other fields.